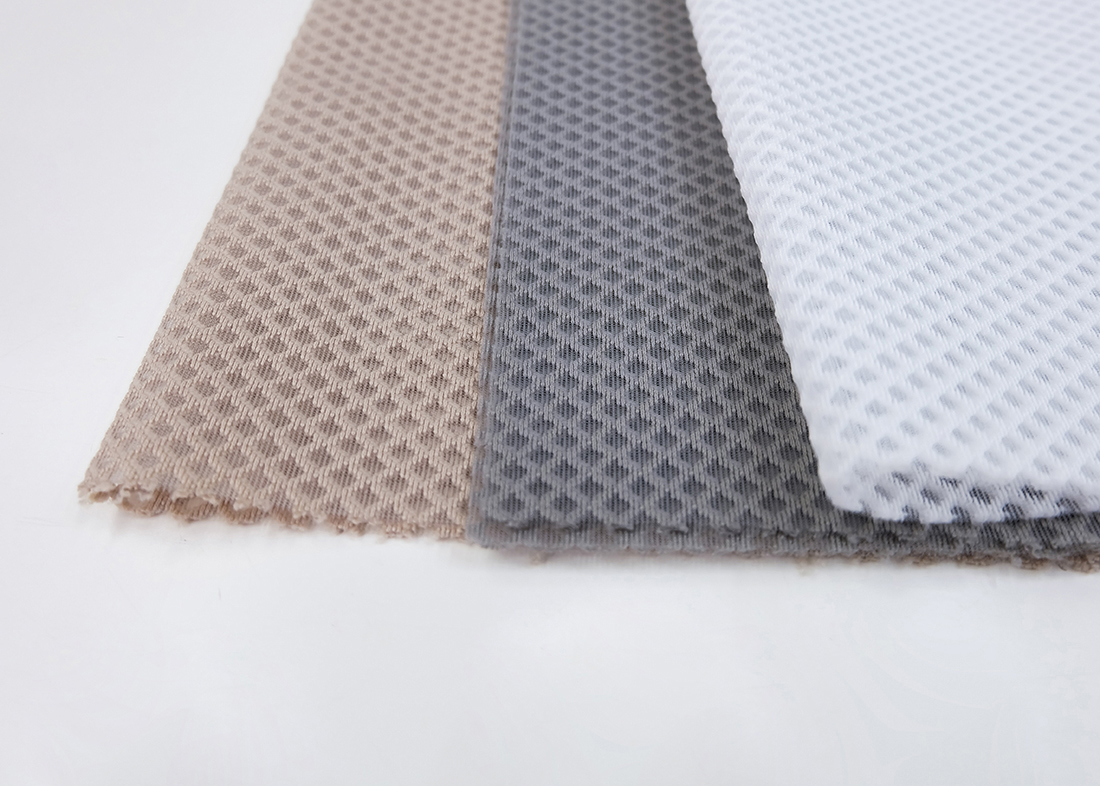

What are the characteristics of 3D mesh fabric

source:sf5566.cn Release time:2024-11-13

3D mesh fabric has the following characteristics:

1. Unique structural design:

Three dimensional structure: 3D mesh fabric is usually a double needle bed knitted mesh fabric, consisting of mesh surface, connected monofilaments, and flat fabric bottom, presenting a three-dimensional structure similar to a sandwich. This structure gives it a hollow characteristic, forming a three-dimensional space that is more complex and unique compared to traditional flat fabrics.

X-90 ° vertical arrangement support: The single fibers in the middle are arranged vertically at X-90 °, breaking through the traditional 0 ° support method for loose fibers. This special arrangement makes the material have a high density and good support performance, with a density even up to 800 times that of a spring, providing good cushioning protection.

2. Good performance:

Good breathability: Due to its unique three-dimensional structure and double-sided mesh design, air and water can freely circulate, forming a humid and hot microcirculatory air layer with good breathability and moisture permeability. Compared to traditional materials such as cotton wool, 3D mesh fabric is less prone to moisture absorption and can effectively avoid problems such as mold and odor caused by moisture.

Good resilience: The material can quickly recover to its original shape and size after being squeezed or stretched by external forces, and has good resilience. This characteristic makes 3D mesh fabric less prone to deformation during long-term use, and can maintain good support and cushioning effects, making it suitable for products such as mattresses and seat cushions that require frequent pressure.

Lightweight texture: The material of 3D mesh fabric is relatively light, which will not add too much weight burden to the product during use, making it easy to handle and install. For example, in products such as car seats and baby strollers, using 3D mesh fabric can reduce overall weight and improve product portability.

Good washability: This material can withstand frequent washing and is not easily damaged or deformed. And its cleaning process is relatively simple, with water flow quickly passing through the mesh, taking away dirt, and good quick drying performance, which can effectively prevent the growth of mites and play a role in mold prevention.

Antistatic performance: It can effectively reduce the generation of static electricity, avoid dust adsorption or discomfort caused by static electricity, and has advantages in some environments and application scenarios that are sensitive to static electricity.

3. Good processability and applicability:

Easy to cut and sew: The material of 3D mesh fabric is soft, easy to cut and sew, and can be processed according to different needs and designs to produce products in various shapes and sizes.

High degree of customization: The nylon monofilament in the middle can be customized according to the different needs of the product, adjusting parameters such as thickness, softness, hardness, density, elasticity, etc., to meet the requirements of different finished products for elasticity and comfort.

Wide application areas: Due to its excellent performance, 3D mesh fabric is widely used in many fields such as mattresses, seat cushions, sofas, car seat cushions, safety helmet pads, outdoor work tool kits, baby strollers, etc.

4. Environmental Protection and Safety:

Environmentally friendly and recyclable: The materials are environmentally friendly and non-toxic, with minimal use of chemical finishing agents and fuel, resulting in minimal pollution to the environment. And after use, it can be recycled and reused, in line with the concept of sustainable development.

Health and safety: It can effectively prevent bacterial and fungal infections, has no harm to human skin, and is suitable for direct contact with the human body, especially in products that come into close contact with the human body such as mattresses and pillows, which have advantages.

1. Unique structural design:

Three dimensional structure: 3D mesh fabric is usually a double needle bed knitted mesh fabric, consisting of mesh surface, connected monofilaments, and flat fabric bottom, presenting a three-dimensional structure similar to a sandwich. This structure gives it a hollow characteristic, forming a three-dimensional space that is more complex and unique compared to traditional flat fabrics.

X-90 ° vertical arrangement support: The single fibers in the middle are arranged vertically at X-90 °, breaking through the traditional 0 ° support method for loose fibers. This special arrangement makes the material have a high density and good support performance, with a density even up to 800 times that of a spring, providing good cushioning protection.

2. Good performance:

Good breathability: Due to its unique three-dimensional structure and double-sided mesh design, air and water can freely circulate, forming a humid and hot microcirculatory air layer with good breathability and moisture permeability. Compared to traditional materials such as cotton wool, 3D mesh fabric is less prone to moisture absorption and can effectively avoid problems such as mold and odor caused by moisture.

Good resilience: The material can quickly recover to its original shape and size after being squeezed or stretched by external forces, and has good resilience. This characteristic makes 3D mesh fabric less prone to deformation during long-term use, and can maintain good support and cushioning effects, making it suitable for products such as mattresses and seat cushions that require frequent pressure.

Lightweight texture: The material of 3D mesh fabric is relatively light, which will not add too much weight burden to the product during use, making it easy to handle and install. For example, in products such as car seats and baby strollers, using 3D mesh fabric can reduce overall weight and improve product portability.

Good washability: This material can withstand frequent washing and is not easily damaged or deformed. And its cleaning process is relatively simple, with water flow quickly passing through the mesh, taking away dirt, and good quick drying performance, which can effectively prevent the growth of mites and play a role in mold prevention.

Antistatic performance: It can effectively reduce the generation of static electricity, avoid dust adsorption or discomfort caused by static electricity, and has advantages in some environments and application scenarios that are sensitive to static electricity.

3. Good processability and applicability:

Easy to cut and sew: The material of 3D mesh fabric is soft, easy to cut and sew, and can be processed according to different needs and designs to produce products in various shapes and sizes.

High degree of customization: The nylon monofilament in the middle can be customized according to the different needs of the product, adjusting parameters such as thickness, softness, hardness, density, elasticity, etc., to meet the requirements of different finished products for elasticity and comfort.

Wide application areas: Due to its excellent performance, 3D mesh fabric is widely used in many fields such as mattresses, seat cushions, sofas, car seat cushions, safety helmet pads, outdoor work tool kits, baby strollers, etc.

4. Environmental Protection and Safety:

Environmentally friendly and recyclable: The materials are environmentally friendly and non-toxic, with minimal use of chemical finishing agents and fuel, resulting in minimal pollution to the environment. And after use, it can be recycled and reused, in line with the concept of sustainable development.

Health and safety: It can effectively prevent bacterial and fungal infections, has no harm to human skin, and is suitable for direct contact with the human body, especially in products that come into close contact with the human body such as mattresses and pillows, which have advantages.

Previous:

Why do many people like sports equipment fabrics

Next:

What are the advantages of mesh fabric for luggag…

wechat number:

wechat number:

Home

Home

WeChat

WeChat

Tell

Tell